Just wondering about the good old machine lifetime replacement plan...

I can remember the suggestions of 7 years before a machine should be considered for replacement.

Now I believe the common census is more like 10 years?

However, providing that the machine is still well supported by whichever company it is made by why not just keep it going until it is no longer supported by the manufacturer?

An unreliable fleet would obviously cause problems if it meant a loss of dialysis to patients but with a good service regime in place I would imagine that the machines are no more problematic than new machines? Most faults should be picked up during the machine's self test anyway so they could be swapped for a spare before a patient is even near it.

Just wondering what people's thoughts are especially when there seems to be little money knocking around for brand new equipment. Is it scaremongering that forces us to change our machines or have people actually consulted their own facts and figures to see if the machines are actually less reliable?

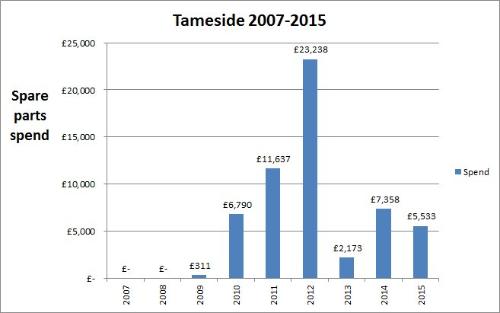

Below is a table of machine data from one of our satellite units showing age of machines against money spent on them (spare parts only, no tech time or service kits included). 22 machines, unit open 6 days a week, 3 shifts a day.

Age wise some might say they are coming to the end of their careers but as a cost to the department, since having some serious investment during year 6 they are now no more costly than when they were 3-4 years old.

We'll have an even better idea in 12-24 months of course but I'd be interested to hear what people have to say on the subject or what your own machine replacement plans are?

Ian Wilde