Hi,

I was looking for a device to test solenoid valved. It's easy to check for continuity and magnetisation, but checking the actual operation is not always easy.

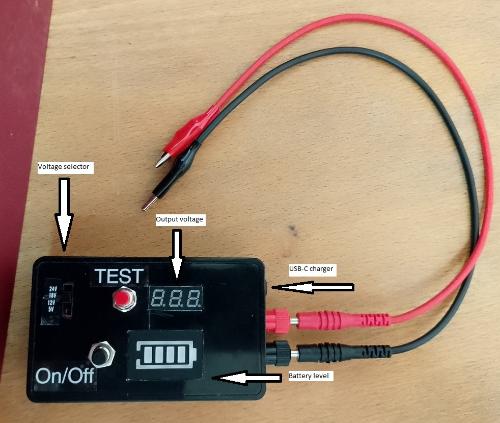

I couldn't find what I wanted, so I made my own.

It has proved useful when checking disinfection valves on Fresenius without the machine then requiring a mandatory disinfection/rinse.

Also used to check chair actuator motors.

If anyone knows where I could get a commercial version that would be good as it was a bit fiddly to make this prototype.

USB rechargeable (battery from a rechargeable vape!), Battery level indicator, output voltage display, capable of 2A - ish.